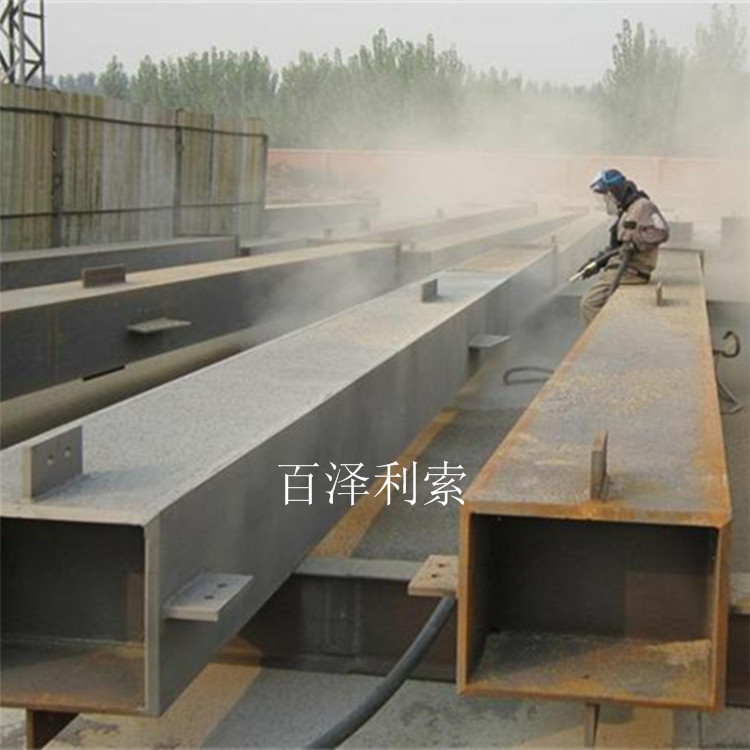

开放式除锈喷砂机喷砂是作为一种常规的磨料射流技术经过不断的发展、提高和完善工机理和广泛的加工、应用范围,使其在当今的表面处理行业中越来越受到青睐,已广泛地应用于机械制造、仪器仪表、医疗器械、电子电器、纺织机械、印染机械、化工机械、食品机械、工具、刃具、量具、模具、玻璃、陶瓷、工艺品、机械修理等等众多领域。

砂料射流是指磨料在某种外动力的作用下,高速运动的磨料所形成的射流。对于干式喷砂而言,外动力是压缩空气;对于液体喷砂而言,外动力为压缩空气和磨液泵的混合作用。磨料是指在射流加工过程中所采用的介质,可以是河砂、海砂、石英砂、刚玉砂、树脂砂、 钢砂、玻璃丸、陶瓷丸、钢丸、不锈钢丸、核桃皮、玉米芯等等不同的材质和粒度,根据不同的喷砂工艺要求进行选择。喷砂与传统的人工处理、机械式处理、化学处理相比,不但成本低、质量高、不会造成环境污染、不会对操作人员的健康造成损害,而且还能实现许多上述工艺方法无法达到的效果。

Sand blasting, as a conventional abrasive jet technology, has been continuously developed, improved and perfected. With its unique processing mechanism and extensive processing and application scope, it has become more and more popular in today's surface treatment industry. Used in machinery manufacturing, instrumentation, medical equipment, electronic appliances, textile machinery, printing and dyeing machinery, chemical machinery, food machinery, tools, cutting tools, measuring tools, molds, glass, ceramics, crafts, machinery repair and many other fields. Abrasive jet refers to the jet formed by abrasive moving at high speed under the action of some external force. For dry blasting, the external force is compressed air; for liquid blasting, the external force is the mixed action of compressed air and a grinding pump. Abrasive refers to the medium used in the jet processing process, which can be river sand, sea sand, quartz sand, corundum sand, resin sand, steel sand, glass shot, ceramic shot, steel shot, stainless steel shot, walnut skin, corn cob And so on different materials and particle sizes, choose according to different blasting process requirements. Compared with traditional manual processing, mechanical processing, and chemical processing, sand blasting not only has low cost, high quality, does not cause environmental pollution, and does not cause damage to the health of the operator. Effect.